Sintered NdFeB (Neodymium-Iron-Boron)

| Category | Details |

|---|---|

| Composition | Neodymium (Nd), Iron (Fe), Boron (B). - Often doped with Dysprosium (Dy) or Terbium (Tb) to enhance temperature resistance. |

| Cost Performance | - High unit price (due to rare-earth content). - Strongest magnetic performance. - Low unit cost per magnetic energy (cost-effective overall). |

| Applications | - Electric vehicle (EV) drive motors. - Wind turbines. - MRI equipment. - Hard disk drives. - Precision instruments (e.g., aerospace/robotics). |

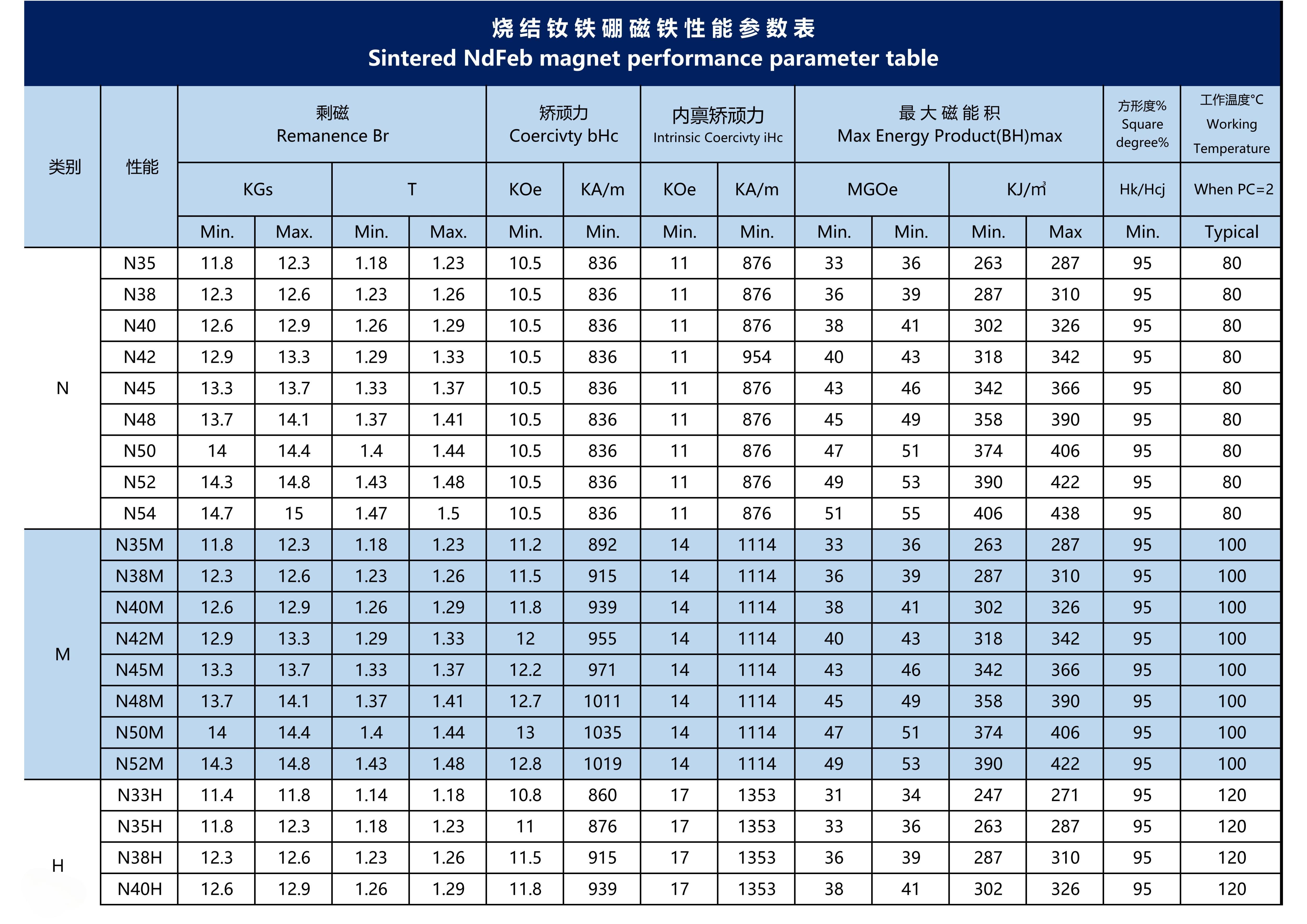

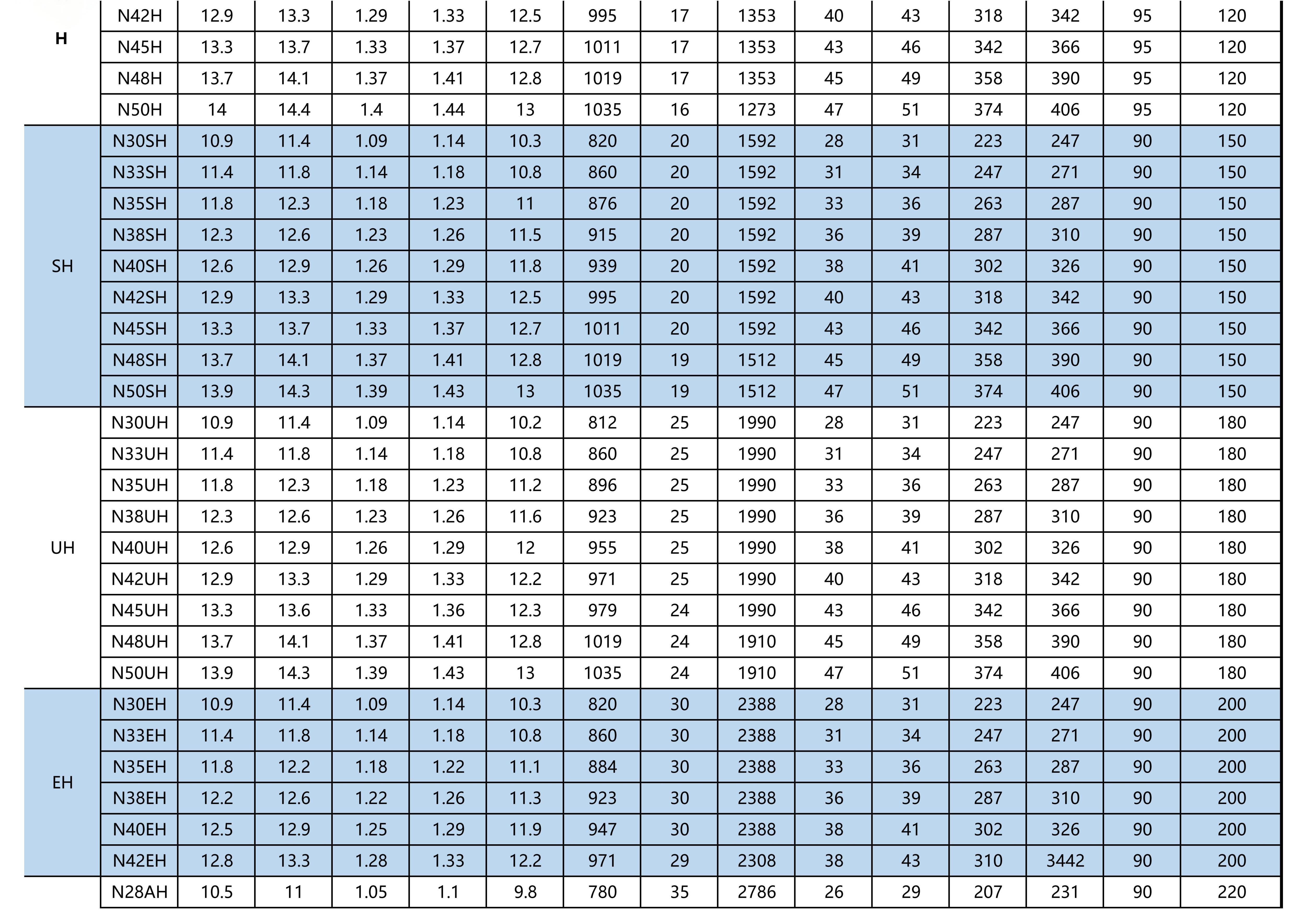

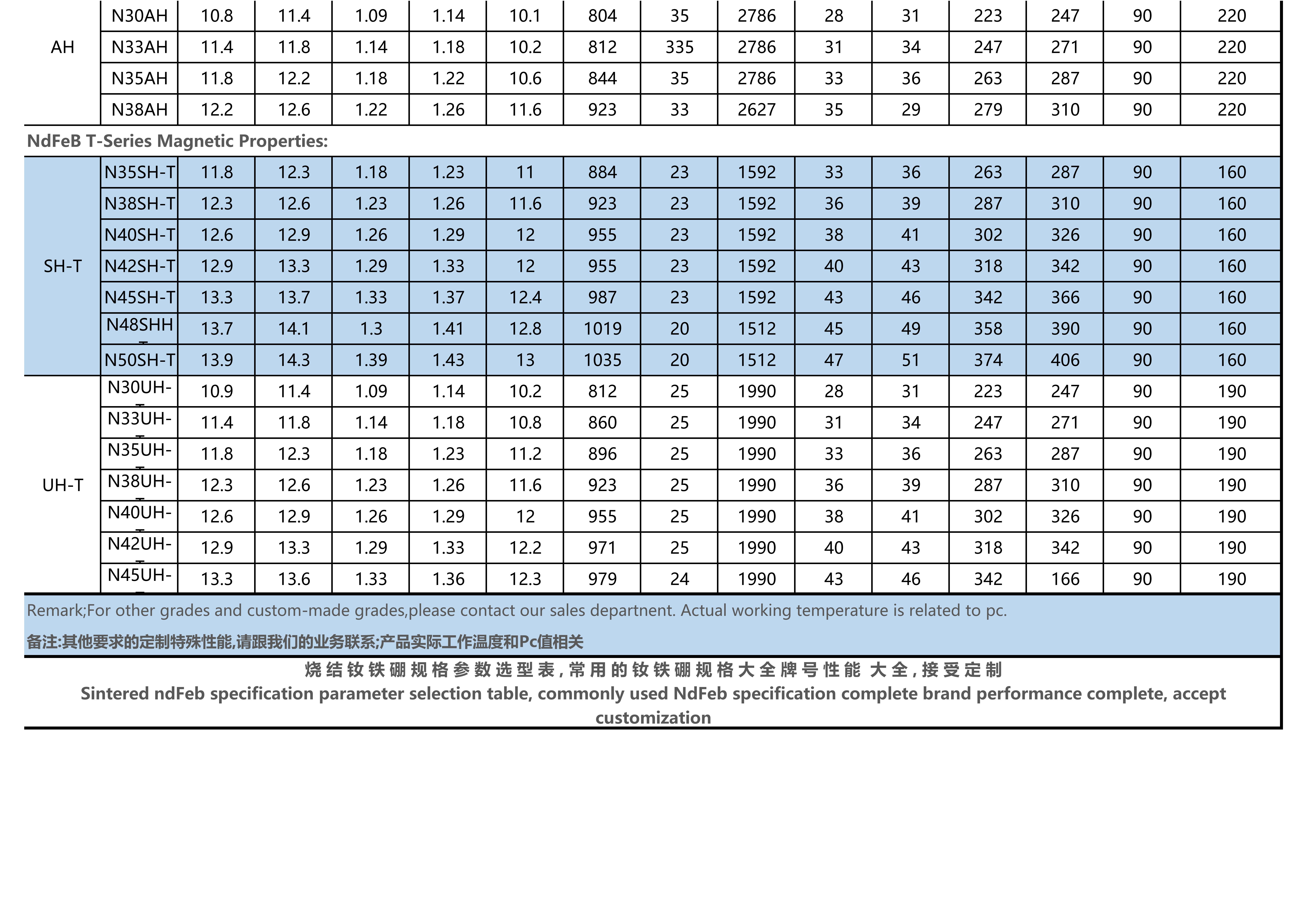

| Magnetic Properties | - Ultra-high magnetic energy product (30–52 MGOe). - Extremely high residual magnetism (Br) and coercivity (Hc). - Poor temperature stability (prone to demagnetization at high temps). - Curie temperature: 310–400°C. |

| Work Environment | - Operating temperature: Up to 150°C (can reach 200°C+ with heavy rare-earth additives). - Susceptible to oxidation; requires protective coatings (nickel, zinc, epoxy). - Brittle and sensitive to mechanical stress. |

Magnetic Strength: NdFeB has the highest magnetic energy (30–52 MGOe), surpassing SmCo (18–32 MGOe), AlNiCo (5–9 MGOe), and Ferrites (3–6 MGOe).

Temperature Limits:

NdFeB works up to 150–200°C (with additives), while SmCo handles 300°C long-term.

AlNiCo has the highest thermal stability (-50–550°C), but weaker magnetism.

Cost: NdFeB is expensive due to rare-earth materials but offers unmatched performance per unit cost. Ferrites are the cheapest.

Durability:

NdFeB requires coatings for corrosion resistance (unlike naturally corrosion-resistant SmCo/Ferrites).

Brittle compared to AlNiCo, limiting use in high-stress environments.

Applications: NdFeB dominates high-tech sectors (EVs, wind energy, medical devices), while SmCo is reserved for extreme environments (military, aerospace), and Ferrites/AlNiCo serve consumer/industrial basics.