Bonded NdFeB Magnet (Bonded Neodymium-Iron-Boron)

| Category | Details |

|---|---|

| Composition | NdFeB magnetic powder mixed with resin/plastic, molded via injection or compression. |

| Cost Performance | - Lower magnetic performance than sintered NdFeB. - Low processing cost, suitable for complex shapes and miniaturization. |

| Applications | - Micro-motors (drones, camera shutters). - Consumer electronics (headphone magnets). - Office equipment (printer rollers). - Smart home components. |

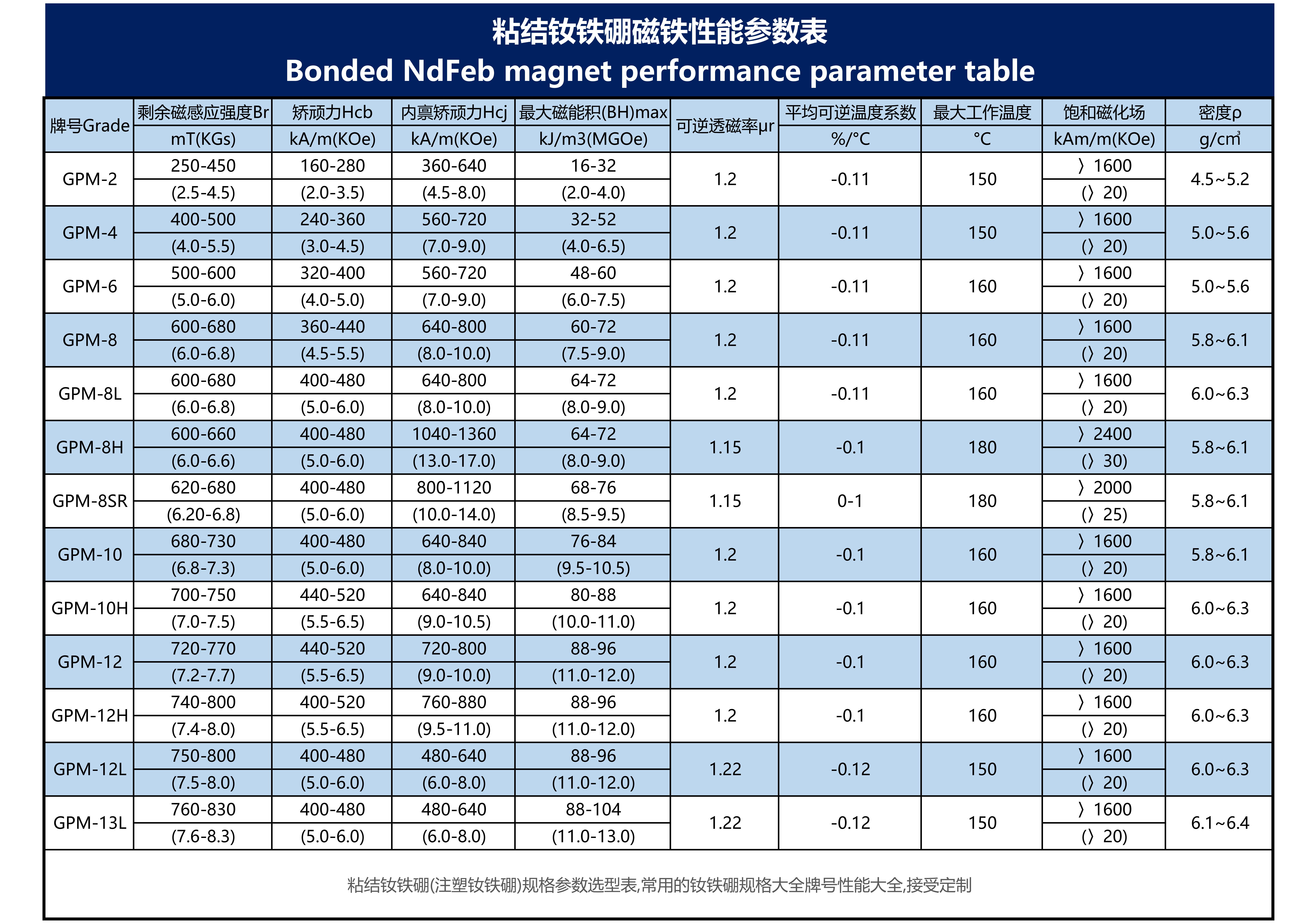

| Magnetic Properties | - Low magnetic energy product (6–15 MGOe). - Moderate remanence (Br) and coercivity (Hc). - Poor temperature stability (max operating temp: ≤150°C). |

| Work Environment | - Poor corrosion resistance (requires epoxy resin coating). - Can be shaped into thin-walled or complex parts. - Better vibration resistance than sintered NdFeB. |

Magnetic Performance vs. Cost:

Bonded NdFeB has lower energy product (6–15 MGOe) than sintered NdFeB (30–52 MGOe) but higher than Ferrites (3–6 MGOe).

Cost-effective for mass-producing intricate shapes (no high-temperature sintering required).

Applications:

Bonded NdFeB: Miniaturized, lightweight applications (e.g., consumer electronics, micro-motors).

Sintered NdFeB: High-performance fields (e.g., EVs, wind turbines).

Ferrites: Low-cost, high-volume uses (e.g., household appliances).

Environmental Adaptability:

Temperature resistance (≤150°C) and corrosion resistance (requires coating) are weaker than SmCo (300°C) and AlNiCo (550°C).

Superior vibration resistance and shape flexibility compared to sintered NdFeB.

Key Advantages:

Design Flexibility: Enables thin-walled, complex geometries via injection molding.